S P E C I F I C A T I O N S

For the

Repair and improvement

Of a

2 manual 10 rank pipe organ

at

First Congregational United Church of Christ

Wadena, MN

Scroll down for

pictures.

1. Remove all pipework from the organ and store in protective trays at the church.

2. Dissassemble organ far enough that the damaged plaster walls behind the organ can be repaired.

3. Transport the windchests to the Moe Piano & Organ Company shop for the installation of new electric chest action.

4. Transport the organ console to the Moe Piano & Organ Company shop for the following repairs and upgrades.

a. Install new solid-state electronic coupler and MIDI system.

i. MIDI system includes a Viscount RD-80e sequencer/sound module with amplifier and speaker.

b. Install new sliver key contacts on the Swell and Great manuals and the pedal board.

c. Install new stop rail with new engraved stop tabs and actions to accommodate the new stoplist.

d. Install new solid-state electronic combination memory system as follows:

i. New keyslips with new pistons.

ii. 4 pistons affecting the Swell stops

1. Swell Cancel

iii. 4 pistons affecting the Great stops

1. Great Cancel

iv. 4 toe studs affecting the Pedal stops

v. 8 general pistons affecting all the stops (5-8 duplicated by toestud)

1. General cancel

vi. Setter piston

vii. Great to Pedal Reversible piston and toe stud

viii. Programmable Sforzando piston and toe stud

ix. Programmable Crescendo sequence

x. 32 levels of memory protected by password

e. Repair broken key on Great manual

f. Install new 12 position transposer

g. Install new MIDI sustain toestud

h. Install new digital control panel for MIDI, memory, and transposer functions.

5. Transport the existing fa็ade pipes to the Moe Piano & Organ Company shop to be repaired and refinished.

6. Deliver restored console, fa็ade pipes, and windchests and install along with the following:

a. New solid-state electronic relay system

b. Up to 50 feet of new main cable between the console and the chamber

7. Clean the organ chambers.

8. Clean all pipework repairing as needed and re-install in organ.

9. Install new electric swell shade operator and necessary linkages.

10. Tonal finish all pipework and tune.

Analysis of Pipes

8 Open Diapason 85 pipes

8 Dulciana 73 pipes

8 Melodia 73 pipes

8 Viole dOrchestra 73 pipes

8 Violin Diapason 73 pipes

16 Stopped Diapason 97 pipes

8 Voix Celeste TC 49 pipes

8 Oboe 73 pipes

16 Bourdon/Lieblich 32 pipes

Chimes 25 notes

New stoplist

Great Organ

8 Open Diapason

8 Melodia

8 Viole dOrchestra (sw)

8 Voix Celeste TC (sw)

8 Dulciana

4 Octave

4 Flute

2 2/3 Twelfth

2 Super Octave

III Mixture (syn)

8 Oboe

Chimes

Great to Great 4

Swell to Great 16

Swell to Great 8

Swell to Great 4

Automatic Pedal

MIDI A

MIDI B

Swell Organ

16 Lieblich Gedeckt

8 Violin Diapason

8 Stopped Diapason

8 Viole

8 Voix Celeste TC

4 Principal

4 Flute DAmour

4 Dulcet

2 2/3 Nazard

2 Flautino

1 1/3 Larigot

8 Oboe

4 Oboe Clarion

Swell to Swell 16

Swell Unison Off

Swell to Swell 4

MIDI A

MIDI B

Tremolo

Pedal Organ

16 Bourdon

16 Lieblich Gedeckt

8 Octave Bass

8 Bass Flute

8 Flauto Dolce

8 Cello

4 Choral Bass

8 Oboe

Great to Pedal 8

Great to Pedal 4

Swell to Pedal 8

Swell to Pedal 4

MIDI A

MIDI B

Pictures

More pictures will be added as work progresses. Be sure to check back often.

The fa็ade pipes. The pipes on the left have

been sandblasted in preparation for

refinishing. The pipes on the right still

have their original gold paint. These pipes

will also be repaired and any dents will

be filled in.

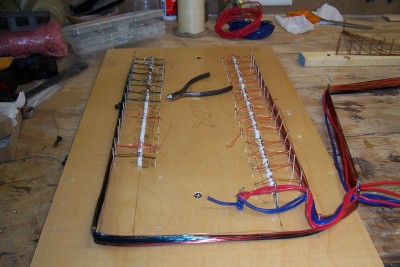

A new chest cable part way through construction. Nylon coated

wire is used to for to keep the cable size small and the make

soldering and assembly much easier. The wire does not need to

be stripped prior to soldering as the nylon coating simply melts off.

A close up view of the nylon coated wire.

Nylon coated wire being soldered onto the connectors for the

solid state driver circuit board.

Interior view of one of the windchests of the organ with the

new chest cable installed. The white devices at the top of the

photo are the electro-magnetic valves which control the flow

of air to the pipes. At the bottom of the picture are four of the

plugs that connect the wiring to the solid state driver circuit board.

This is my trusty assistant Alex. He is 2 ฝ and has a good time

helping his dad J

Here is one of the two main windchests in this organ prior to

wiring. The chest shell is new contruction and the boards to

which the electro-magnetic valves are attached are original to

the organ. New chest shells were required for this organ in order

to make room for the new electro-magnetic valves which replace

a deteriorated electro-pneumatic chest action.

This is an ants eye view of one rank or valves looking down

the length of the windchest.

Here is the same windchest after being wired. All the wiring

and the solid state driver circuit boards are contained within the

windchest. This eliminates the need for a bulky cable running

through the organ chamber. The only connection to the windchest

is made with a CAT5 ethernet cable like you might connect to

computer.

Here are the solid state driver circuit boards installed in the

windchest. They utilize transistors and other solid state

electronic components to interpret the signals from the organ

console and open the appropriate valves.

Here is the existing console prior to disassembly. The organ was

built in 1924 by the M. P. Moller company of Hagerstown, MD.

Back view of the console prior to disassembly.

View behind the existing stop tabs.

Back view of the console after all the old components have

been removed.

The old guts from the console waiting for the scrap heap.

The new stop tabs waiting to be installed in the console. The

old stop tabs are in the background.

New tablet board, stop actions, and circuit

boards installed in console and awaiting

wiring.

Main console wiring harness all run and waiting to be laced.

Close up view of part of the main console harness. This part of

the harness connects to the combination action circuit board and

operates the stops tabs and thumb pistons.

Close up view of part of the main console cable after being laced up.

Front of console after installing new equipment. The brass panel

on the lower right is for controlling the various features of the new

electrical system.

Rear view of console showing wiring and circuit boards. AC cords

at the bottom of the picture are awaiting an outlet to be plugged into.

This is the area directly behind the new stop tabs.

The new stop actions to which the tabs are

attached are in a line on the left.

View behind the control panel. The square circuit board at top center

is the back of the control panel. The large circuit board at bottom center

is the new combination memory system.

Re-installation is

begun!

This is the organ chamber in the church. Shown are the legs and

regulators for the organ.

Another view of the organ chamber area showing the main and

pedal regulators.

16 Bourdon pipes awaiting installation.

Zinc basses of the Diapason, Viole, Dulciana, and Violin Diapason

awaiting installation.

This is the storage room at the church where the pipes and casework

of the organ were stored while the organ was being restored.

One of three beautiful stained glass windows

in the sanctuary of this church.

Damaged pipe. Damage caused be HVAC installers.

16 Bourdon pipes installed on the rebuilt winchest.

Main winchests installed in organ chamber. The original topboards

(brown in the picture) were retained and installed on new chest

shells (white) with new electric action.

Andrew installing casework supports on new windchests.

Swell shade frames and casework installed on new windchest.

Swell shades and remaining casework installed. Organ is now fully

enclosed and awaiting pipes.

This is a view into the organ chamber after the pipes have been

installed.

The casework is back, now for the fa็ade pipes.

Here are the fa็ade pipes in 3 stages of repair. The pipes on the left

have been sandblasted and the dents have been filled. The 3 pipes on

the right have been painted with 2 coats of gold metallic paint and 1 coat

of clear laquer. The three pipes to the left of the 3 completed pipes

have only one coat of gold on them.

Here are some more completed pipes ready to go back in the organ.

Organ completely installed with newly restored fa็ade pipes in place.

Another view of the organ from the console.

All work

complete!!