Immanuel Lutheran Church

Project Blog

Check back often for new posts which will appear at the bottom of the page.

You can email questions and comments to info@moepipeorgan.com

Click here to return to our home page.

5/16/11

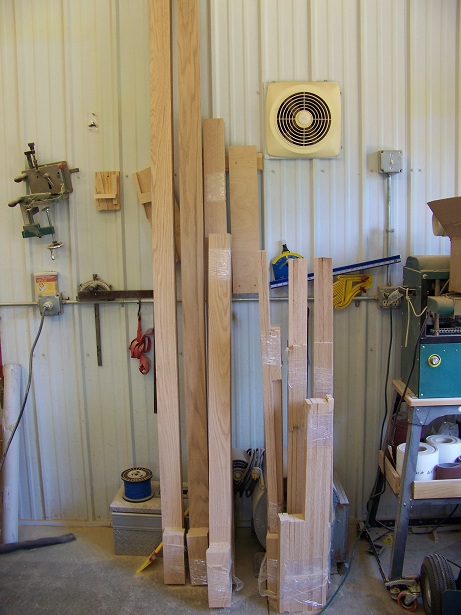

The new pipes have been ordered and the lumber has been delivered to the shop. Today I begin the process

of turning about 1000 board feet of Oak and Hard Maple into the organ you see at the top of this page.

5/16/11

Click here to download the stoplist for this organ.

6/21/11

Now that spring tuning season is finally out of the way I can get back to work on Immanuel's new organ.

Today I removed the old organ in preparation for beginning offical construction of the new organ. Above is a picture of the old organ prior to removal.

The organ console. The new organ will have a different console with many more stops. It will also be located in the front of the church on a movable platform.

The old organ as seen from the organist's point of view while seated at the console.

The pipes inside the old organ. These pipes will be used in the new organ and will make up about half of the Swell division.

The pipes are all gone!

Here they are. The pipes are all stored in protective cardboard trays until it is time to put them back in the new organ.

This is the main windchest for the old organ. It contains all the valves which control the flow of air to the pipes. It will be incorporated into the new organ as the main windchest of the swell division.

The organ is officially un-installed.

Now its officially unistalled. The Leiblich Gedeckt is down off the ceiling. I've never seen another organ with this type of pipes mount horizontally as part of the visual aspect of the instrument. Very unusual!

6/29/11

These are the four auxilliary beams which will extend from the main steel I-beams to the outside walls of the church. They are each 3" x 6" and 11' long and are made of solid hard maple. They will transfer the entire weight of the organ to the sidewalls and to the I-beams.

Most of the wood for the organ has been cut. Here is some of the oak for the components of the casework including the mullions on the upright towers as well as the frames for the frame and panel casework sections.

Here are more of the beams which form the foundations of the organ as well as the toe boards for the windchests which will hold the pipes. Again, all is solid hard maple.

More cut lumber. The white lumber is all the various pieces fo the windchests of the organ. In the 3 cardboard boxes are the pieces which will form the crowns of the upright pipe towers.

These 3 boxes contain several hunred small pieces of oak which will be mitered together to form the complex curves of the tower crowns.

6" X 6" X 20ft steel I-beams. These go in the balcony to support the weight of the organ.

Me, myself, and I unloaded them in the church parking lot. Between the three of us we managed without too much trouble.

7/2/11

One of three new windchests for the organ. This one will hold the pipes of the 4' Octave, 8' Erzahler, 2 2/3' Twelth, 2' Fifteenth, and III Mixture in the Great division of the organ. The windchests are made of hard maple for strength and durability. The silver screws are installed for clamping pressure while the glue dries. They are then removed and replaced by 1/2" dowels.

7/8/11

Very busy day onsite in the church.

Today is the day the steel I-beams get put in place. The shiny metal contraption to the right is the hoist which will lift them up to balcony level.

Here comes the first beam. They are very heavy. Mark Stone very helpfully provided two of his workers to assist with getting the beams into place.

Here we go. Its a good thing there are double doors or we wouldn't have made the corner inside.

Thank goodness there was a ramp, carrying these up the steps would not have been fun!

Again, thank goodness for double doors!

The beam is lifted above the pews and then rolled into place on the lift.

Up we go.

Kevin being goofy.

Pull harder guys, nothing's happening.

Ok, now we're getting somewhere.

Ellen and Tahna are concerned that the pews will tip over so they're holding on for all their worth!

Once more, with feeling! Ellen appears to be praying for our success.

We take a break while Christie fulfills her life long dream of walking on the backs of the pews!

Meanwhile, the beam is stuck.

Kevin descends into "The Hole" to see what's going on. This hole gives access to the space between the balcony floor and the ceiling of the Narthex below. This is also where the back ends of the beams will be anchored to the East wall (masonry) of the church to provide support for the cantilever.

After moving some conduit out of the way under the balcony the beam continues its journey. Mark Stone arrives just in time to give a few tugs as the beam slides into place.

Kevin returns from "The Hole"

The second beam will go into this hole. It was installed through the same process as the first one.

Now its time to get the old organ console out of the balcony since we have the lift on site. Here's the console in its original location. Its the wooden cabinet with the television on top of it.

The first step is to get some more pews out of the way. To do this, they are unscrewed from the floor and then stood up on end in the isle.

Then I turn them 90 degrees and put them back down in the isle.

Since the balcony railing has to go away for the new organ to go in this seemed like a good time to take it down. So, a section is cut out to allow for easier access to the organ console. The console's back is visible at the top of the lift.

The console is set on the forks of the lift and strapped down. The pad protects it from the sliding metal parts of the lift. You can also see the 2nd I-beam in this picture to the left of the console.

The console is on the lift.

"Don't worry, I've done this before" is what I told Ellen who was taking the picture.

Down we go.

Its been up there since 1962.

The console is gone. Now, more of the railing will be removed in the center to gain access to the piano.

The piano, a Wurlitzer spinet, is laid on its back on the lift with bracing to protect the soundboard and lowered to the floor. Being tipped over like this does no harm to the piano and is a much more stable and safe way to handle the instrument on this type of lift.

The balcony railing is gone. Next step will be to secure the I-beams in place and then install the rest of the Maple beam structure which will extend from each I-beam to the outside walls of the church.

7/15/11

Two of the casework panels with inset moldings and "book-matched" veneer. The panel on the right is upside-down, otherwise the veneers in these two panels match very closely.

Closeup of the molding

This is part of the complex molding that forms the top crowns of the smaller towers of pipes.

Another section of molding for the large corner towers of pipes.

Also this week the I-beams in the balcony were secured in place the the adapters were attached to their ends for transitioning to the Maple beams which will be installed next week.

8/5/11

In the past couple of weeks much work has been accomplished in the shop. Soon the casework and windchests of the organ will be installed in the church.

This is one of 16 mullions for the case of the organ. Mullions are the upright timbers which support the towers of pipes as shown in the drawing at the top of this page.

Here is one of the pipe towers assembled in the shop. The mullions are the upright posts on either side. The windchest at the bottom will contain the valves and mechanism to operate the 5 pipes which will stand in the holes on the curved part of the chest. The complex crown is on the top of the mullions. There will also be a decorative gothic inspired "pipe shade" that will extend downward from the crown.

A closeup showing the complicate angles of the tower crown.

Another closeup of the crown.

8/10/11

The next set of pipe towers are put together.

8/12/11

This pile of blocks is only about 1/5 of the 400 individual pieces required for the 4 large corner crowns!

The 4 large corner towers are assembled. These are the two that are facing out into the church. Next step is to break them down into the separate components and get the stain and clear finish on them. Then its off to the church!

8/26/11

All the woodwork of the organ case is stained and ready for the clear coat. Here are the crowns and windchests ready to be sprayed.

This is the "new" console. This console was built for St. John's Lutheran in Dickinson, ND by the Austin company in 1950. It will be restored and updated to control our new organ.

Here's the interior of the console with all the new stops installed. Also installed are the LCD control panels.

9/9/11

The casework has been installed along with the interior framing and windchests.

The Great casework on the South side of the church. The Swell is on the opposite side.

Close up of the case from below.

The pipes are in and its playing. Voicing is currently underway. The final pieces of the casework as well as the Fanfare Trumpet (en chamade) will be installed in the weeks leading up to Christmas.